Hardware

Advanced intelligent system

With the combination of development technology in knowledge-based software and rich engineering technology, we have developed the highest level of industrial hardware products and help our partners to manufacture the high quality products with better noise and vibration performance. The developed H/W by CreaTech is listed below.

- Active/semi-active vibration/force compensator for ship’s structures and diesel engines

- CMS for machinery and hull structures

- Acoustic Enclosure for Land and Maritime Use

- RAC Acoustic Chamber

Active/semi-active vibration/force compensator for ship’s structures and diesel engines

- Excessive Vibration Responses on ship’s structure is causing fatigue damages of structures and vulnerable habitability.

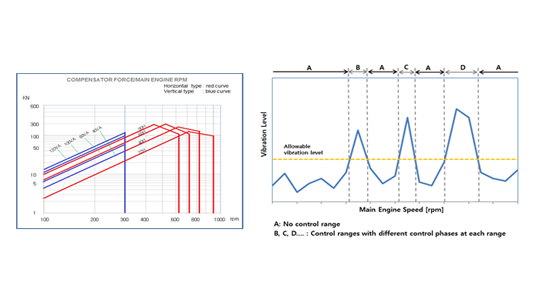

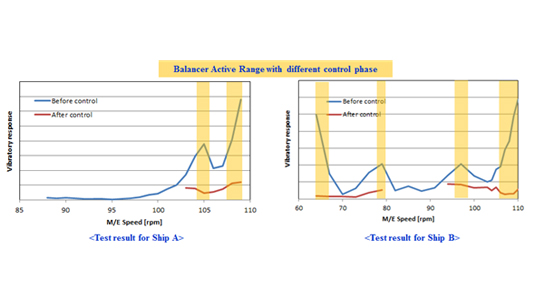

Mainly coming from ship’s propulsion system, M/E and propeller. - Real-time control algorithm & DSP board producing accurate control force

- Product design including mechanical & electric components

- Energy saving technology Multi-selectable operating speed ranges with different control orders and phases

- 2 types actuator according to forcing direction, Horizontal & Vertical

- 8 types products according to control force magnitudes

- Performance confirmation during several sea trials, including basic control abilities and energy saving technology

- Deliver over 30 products to domestic/international ship yards & marine engine builders, based on 2016 year

- Patent register No. 10-1202679 “ Drive method of control system to reduce ship vibration”

-

Active/semi-active vibration/force

compensator in horizontal & vertical directions

-

-

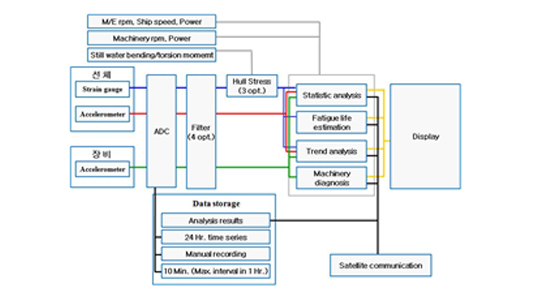

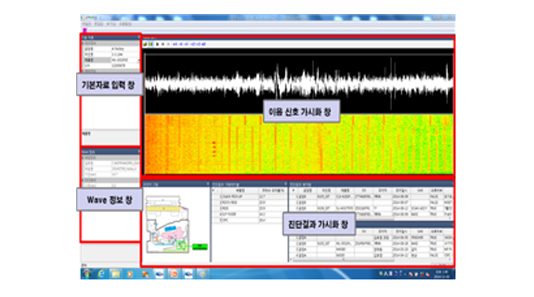

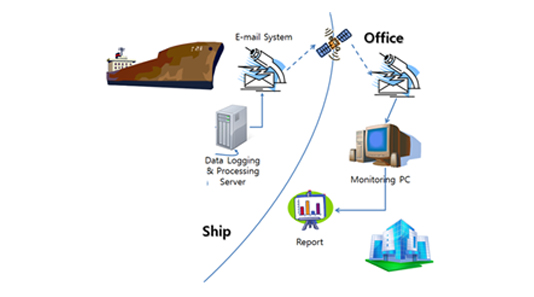

CMS (Condition Monitoring System) for machinery and hull structures (collaborated with HHI)

- Integrated System with H/W, S/W & Engineering Algorithm

- STX marine service & Hyundai Shipping: On-board EEOI monitoring system using a PC and without any data gathering H/W

- HHI: CMS up to 200 Ch. with data gathering & diagnosis function for machinery & hull structure by using vibration, strain gage signals

- Samsung Electronics: Fault diagnosis system for printers at producing line by using “Sound Quality Analysis”

-

CMS for marine & offshore structures

-

Fault Diagnosis System using SQ

-

EEOI monitoring system

Acoustic Enclosure for Land and Maritime Use

- Protects against excessive noise that can cause hearing loss

- Optimal Design considering the noise characteristics of target equipment

- Design considering the installation environment(Hinge & Sliding door type and acoustic louver design etc.)

- Applying an appropriate solutions for performance satisfaction through the required performance analysis

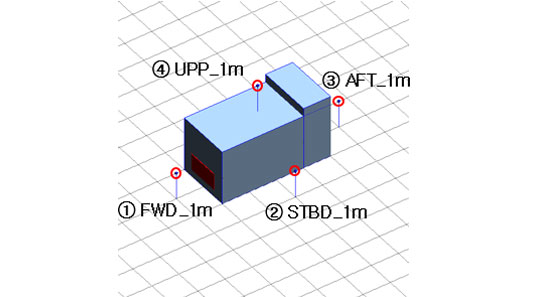

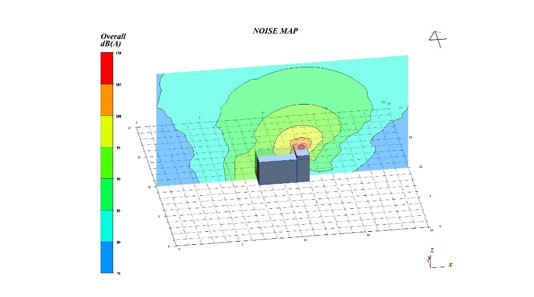

- Noise prediction design and analysis considering acoustic transmission characteristics

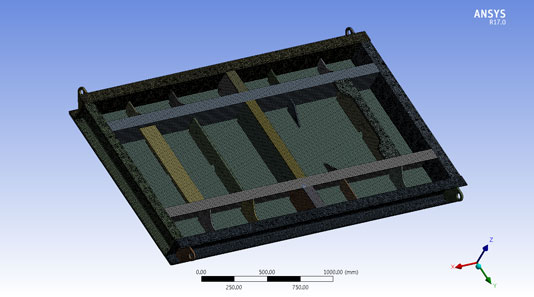

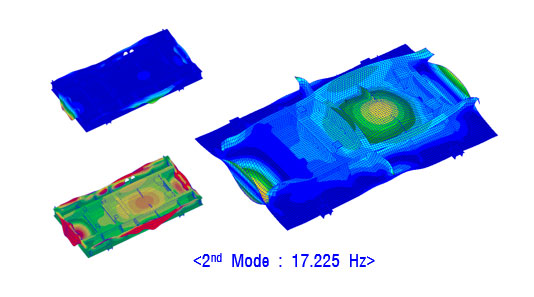

- Structure and Vibration analysis for acoustic enclosure, Dynamic stiffness analysis for optimal rubber mount selection, Resonance Mode analysis

- Calculation of required ventilation air volume for optimal ventilation Fan, Thermal Fluid analysis

- Integrated design process for performance assurance

-

Equipment

noise analysisAnalysis for equipment noise data

-

Noise prediction

designRequired noise level simulation

RFP, POS review -

Basic

designSelection of Dimension and Sound material

Base frame Design

Selection of Anti-vibration mount

Air Intake Louver design

Required ventilation calculation

Selection of Fan / Silencer design -

Analysis

Structure and Vibration analysis for acoustic enclosure

Structure analysis for base frame

Resonance mode analysis

Dynamic stiffness analysis

Thermal fluid analysis

Structure and acoustic analysis for Silencer -

Final Test

Test according to the test procedure

Issuance of Official Report, if necessary

Submission of noise measurement report

Assurance of design and analysis, manufacture -

Pre-Test

Noise Reduction measurement

Performance prediction through IL(Insertion Loss) evaluation -

Production

Material Order

Bending/Welding/Machining/Assembly/Painting -

Detailed

designCreate a detailed drawing based on the approved drawing

Create sound insulation panel and Door assembly drawing

Base frame cutting/Assembly drawing

Louver/Fan silencer manufacture/Drawing

Pipe drawing

-

3D Design for acoustic enclosure

-

Mode analysis for sound insulation panel

-

Structure and vibration analysis for Base frame

-

-

Radiated noise analysis for acoustic enclosure

-

-

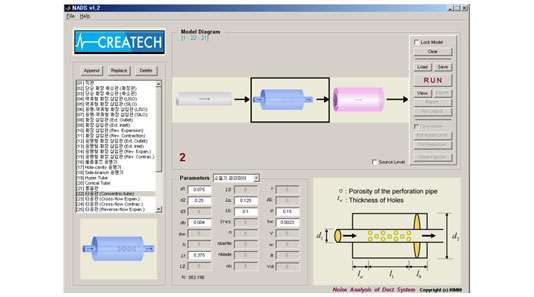

Design and analysis for Silencer

-

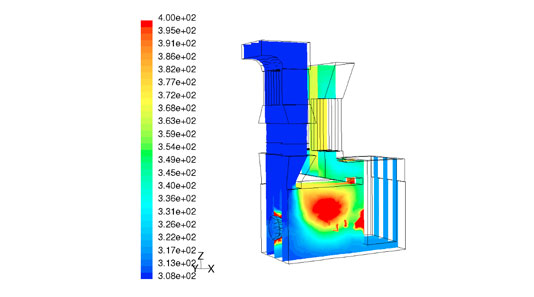

Thermal Fluid analysis

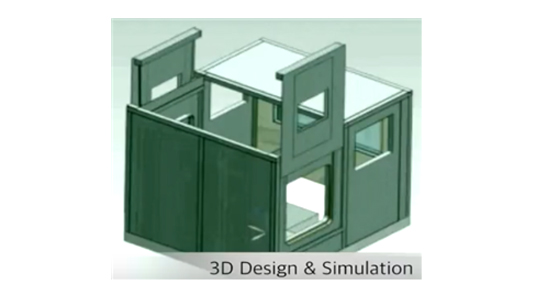

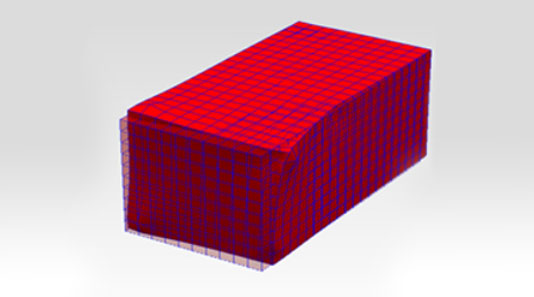

RAC Acoustic Chamber(Collaborated with *RAC manufacture, SAMSUNG Electronics)

- Design and manufacture of acoustic chamber for RAC’s automation noise inspection

- Selection of proper solutions to meet the requested noise criteria

- - Window type : triplex laminated glass

- - Seal type : silicone foam gasket

- - Door type : automatic sliding door (vertical type)

- Development of automatic sliding door considering noise performance & convenience

- Automatic control PLC system considering a safety inspection

-

Acoustic Chamber for RAC

-

3D Design & Simulation